Aerospace Hydraulic Filtration Systems & Assemblies

For over 20 years Norman Filters has worked extensively with leading Aerospace companies that are on the cutting edge of space flight development. NFC designs, manufactures, and tests aircraft filters, elements, and systems in-house for manned and unmanned space flight applications. Whether Inline or T-Type, we have pedigreed filtration units in use for mid and high-flow applications that require all-welded stainless-steel elements.

Norman is continually working towards expanding the science of filtration through investment in in-house test capabilities, company led R&D projects, and joint projects with our partners in order to grow with the ever-expanding space flight community.

Norman Filters have passed the rigorous testing required for use in mission-critical applications for Aerospace companies. All machining, welding, inspection, and precision measurement is accomplished under our AS9100 quality system requirements.

NFC has experience manufacturing filters with the following materials:

- 303 Stainless Steel

- 304/304L Stainless Steel

- 316/316L Stainless Steel

- 17-4 Stainless Steel

- Hastelloy

- A286 Stainless Steel

- Aluminum Raw Bar Stock

- Monel

- Inconel

- Zirconium

NFC also has experience with less common metals such as Titanium and Nickel. Titanium is a common metal used in Aerospace applications for its ability to resist heat and corrosion. Nickel is utilized in Aerospace applications due to its immense strength and corrosion-resistant properties.

NFC has serviced an array of Aerospace systems that have utilized our high-pressure high-flow filters including:

Ground Support Equipment

NFC provides filtration solutions to leading commercial Aerospace companies. Our entire range of standard and custom filters are heavily used in aerospace ground support and flight applications with wide range of customizable configurations such as AS1098 seal cuts in male fittings.

Applications:

Feed & Fill Lines, Gas Pressurization, Fueling Services, De-Icing, Hydraulic Fluid Services

Filter Series:

4500, 4200, Cone/Witches Hat, 4900, 4300, 79K Series

Media Supported:

Cryogens: Liquid Oxygen/Helium/Hydrogen, RP-1, Water Glycol, Propylene Glycol, GOX, H2, He, GN2

Manned & Unmanned Space Flight

Norman Filters can be found in operation aboard manned and unmanned space flight applications. Our team has provided unique geometry components constrained by limited available space or complicated interface dimensions. NFC Engineering has experience delivering products that meets and exceeds the demand of mission critical space flight applications.

Applications:

Engine Propulsion, Oxygen Services, Hydrazine Filtration, Thrust Vector Control (TVC) and Reactional Control Systems (RCS), Propellant Tank Flow and Pressurization System.

Filter Series:

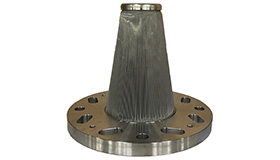

4200, Cone/Witches Hat, Custom Inline Tubelet, Filter Screens/Baskets

Media Supported:

Cryogens: Liquid Oxygen/Helium/Hydrogen, RP-1, Hydrazine, Helium, Nitrogen

International Space Station

Norman Filters is proud to be aboard the International Space Station.

Aerospace Testing Capabilities

Norman has and will continue to acquire the appropriate testing equipment to support unique projects that push the limits of Aerospace filtration.

Our team has a variety of in-house test stands that we operate to any specifications for any Aerospace application from Ground Support to Manned and Unmanned Space Flight operations. Norman’s aerospace testing capabilities include:

- Liquid and Pneumatic Flow Testing: Flow testing is performed to understand the differential pressure across the filter media (element). NFC has the ability to perform flow testing using water, hydraulic fluid, propylene glycol, JA, for liquid applications and nitrogen helium for gaseous applications.

- High Flow Testing: Up to 8,000 GPM water measuring volumetric flow rate and low-pressure differential measurement capabilities, this test stand serves to simulate the flow of the rocket propulsion system through our filters.

- Proof and Burst Pressure: Hydrostatic test chamber capable of pressure up to 120,000 PSI. Gaseous proof up to 25,000 PSI.

- Cryogenic Sealing Test: Conducted by submerging our filter assembly into liquid nitrogen where the filter is soaked for a designated period of time to ensure sealing surface is not affected by thermal expansion/contraction.

- Thermal Flow: This test allows for replication of exact fluid temperatures our filter will endure during its life while measuring pressure differential.

- Dirt Loading: Using calibrated test dust, this measures differential pressure across the filter while contaminant is added to the system. NFC can perform this test to a specified amount of contaminant added, specific differential pressure or element collapse.

- Slam Start: NFC created this test for gas applications which utilizes high frequency pressure sensors and a fast-acting solenoid valve to simulate rapid system pressurization at 0 - MAWP ~ 10 ms.

- Water Hammer: Testing for liquid applications, water is run through the filter element simulating rapid valve actuation. The data is used to set an acceptable gas accumulation limit. (Includes an initial vacuum pressure test upon request).

- Vacuum Chamber: 1x10^-6 std.cc/sec mass spectrometer for Helium leak detection under vacuum.